Our Solutions

Your Vision Guides Us When We Develop Machines

The MRB Automation team develops and manufactures high-precision machines and systems that are specific to the needs of each individual customer. These are used in adjustment processes in particular, such as for measuring and testing individual parts and assemblies, and for calibrating sensors. Our team will take on your demanding tasks and do their utmost to complete them to your full satisfaction. Whatever your requirements are, state-of-the-art image processing systems, high-resolution positioning systems, complex measuring techniques, comprehensive modular software packages and employee expertise will come together to create something truly remarkable.

Take a look at some of our project testimonials, they speak for themselves.

Alignment Systems

Measuring and Testing Systems

Calibration Systems

Manufacturing Precision Parts

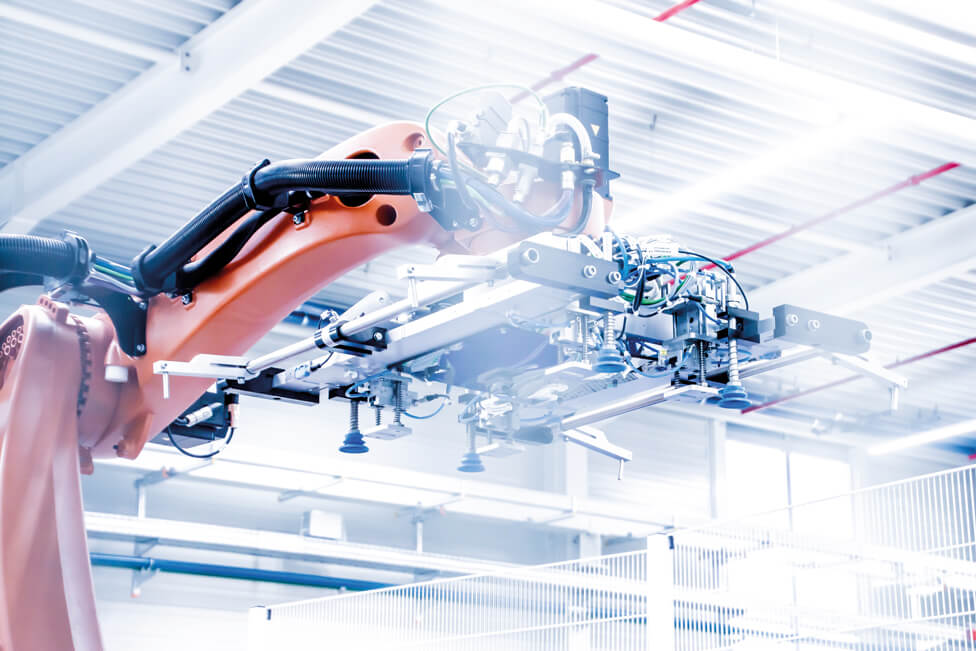

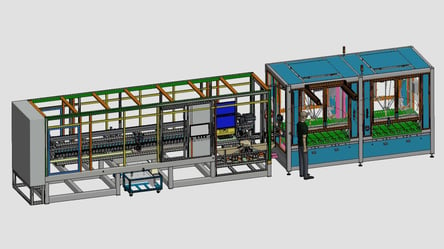

Alignment Systems

MRB Automation develops adjustment systems for adjusting a wide variety of parts with accuracies down to the nearest micrometer or sub-micrometer. We develop and select the adjustment principle and the technology we need to use based on your specific requirements. This approach guarantees that your alignment will be consistently accurate every time, even in large-scale production.

MRB Automation develops adjustment systems for adjusting a wide variety of parts with accuracies down to the nearest micrometer or sub-micrometer. We develop and select the adjustment principle and the technology we need to use based on your specific requirements. This approach guarantees that your alignment will be consistently accurate every time, even in large-scale production.

-

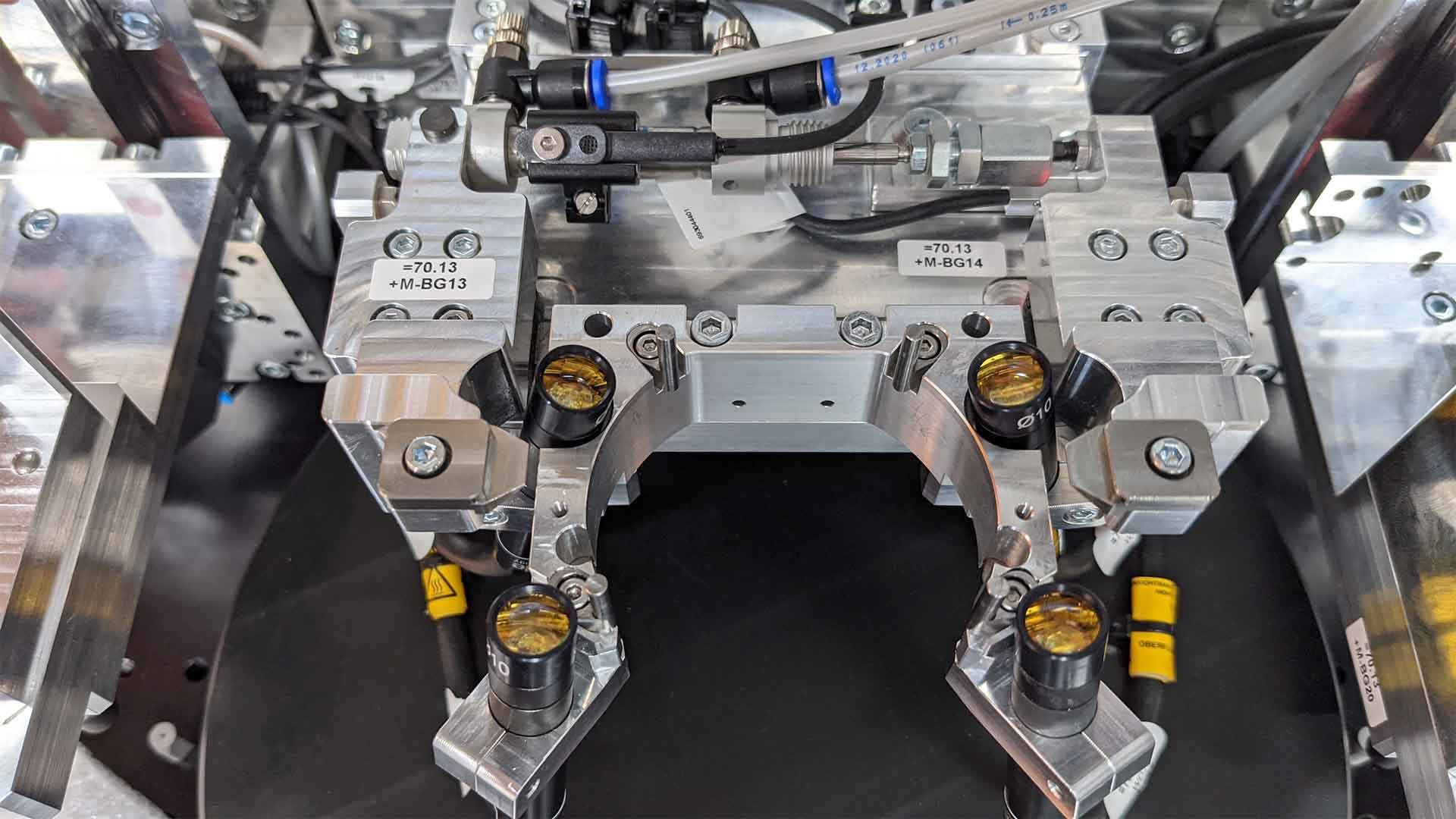

Alignment System for PHB Headlights (Permanent High Beam)

-

Alignment System for BiLED Headlights

-

Alignment System for HD-SSL Headlights (Solid State Lighting – High Definition)

Our adjustment system for PHB headlights will keep the roads powerfully lit to keep you safe. Precise measurement & adjustment to the nearest micrometer is crucial for this, and even landed us the Thuringian Innovation Prize in 2016 for our development of the PHB adjustment system.

Alignment Tasks

Alignment Tasks

- Aligning primary optics to light sources

- Measuring 90 LEDs on a PCB using cameras and confocal sensors

- Measuring primary optics made of silicone with cameras and confocal sensors

Technology

- Granite block with vibration dampers as a base

- Dual station, parts feeding via robot

- Alignment with hexapods (resolution 0.1 μm)

- Automatic calibration of all the measuring equipment

- Automatic MSA mode

- Transmitting data to the MES in real time

- Visualizing extensive results using LabVIEW

- Alignment control with 3 gap-measuring cameras

- UV curing

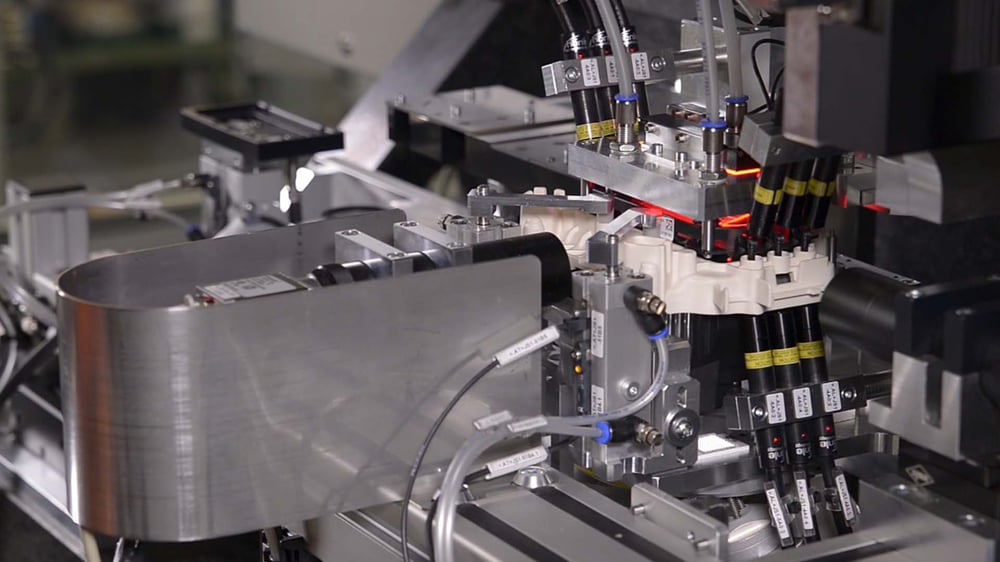

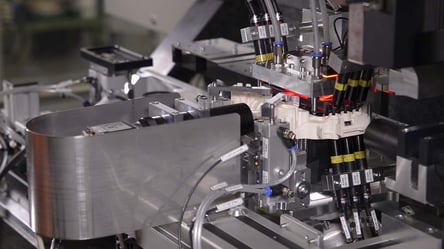

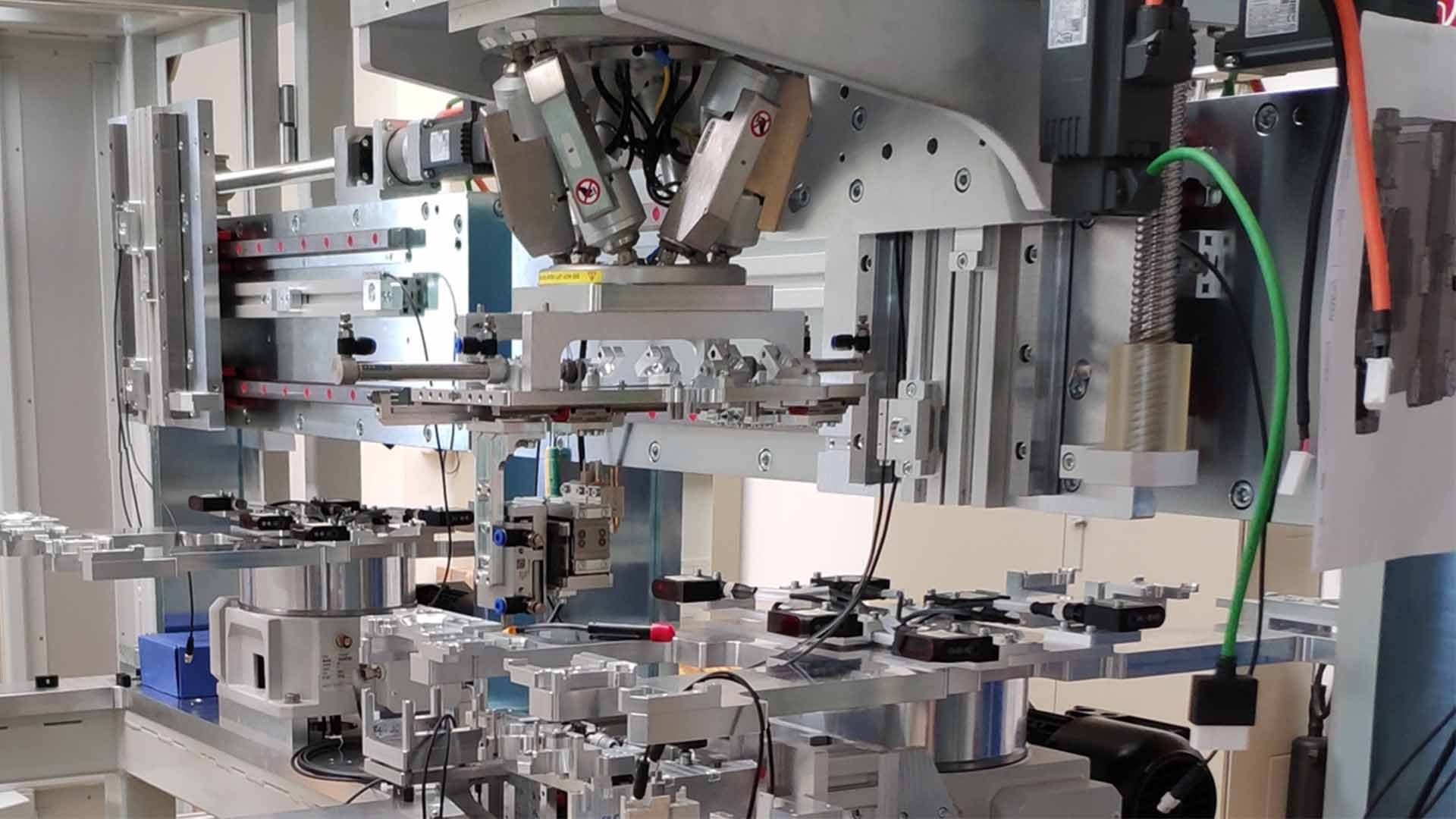

The BiLED headlight lights the road up beautifully with a built-in high beam and low beam. We’ve developed an adjustment system specifically for this.

Alignment Tasks

- Simultaneously aligning two polycarbonate primary optics to LED arrays

- Adjusting components in the micrometer range in all 6 degrees of freedom

- Measuring the LED positions on the PCBs with cameras and confocal sensors

- Measuring primary optics with cameras and tactile probes

Technology

- Granite block with vibration dampers as a base

- Alignment with 2 robots

- Optical position monitoring and correction for the robots

- Adjusting 50 different variants without the need for a make-ready process or any interruptions

- Automatic calibration of all the measuring equipment

- Automatic MSA mode

- Transmitting data to the MES in real time

- Visualizing extensive results using LabVIEW

- UV curing

- Integration into a complex production line

30,000 LED pixels ensure a high light output and a wide range of functions in HD-SSL headlights. Our innovation ensures that they can be properly adjusted to guarantee exceptional performance.

Alignment Tasks

- Aligning the primary optics to the light image of the SSL-HD chip on the PCB

- Measuring 90 LEDs on a PCB using cameras and confocal sensors

- Geometric measurement of primary optics made of silicone with cameras and confocal sensors

Technology

- Dual station, parts feeding via a rotary indexing table

- Alignment with hexapods (resolution 0.1 μm)

- Automatic calibration of all the measuring equipment

- Automatic MSA mode

- Transmitting data to the MES in real time

- Visualizing extensive results using LabVIEW

- UV curing

Measuring and Testing Systems

Are you looking for simple and safe, high-precision measuring and testing systems? MRB Automation is the partner for measuring systems and testing machines you need, as we also test parts in ranges below one micrometer. We provide one hundred percent quality control so that your customers are satisfied too. Whether it’s optical, pneumatic or electrical, we always choose the most appropriate measuring method for your complex task. Our measuring and testing systems record, visualize and statistically evaluate all measured values.

Are you looking for simple and safe, high-precision measuring and testing systems? MRB Automation is the partner for measuring systems and testing machines you need, as we also test parts in ranges below one micrometer. We provide one hundred percent quality control so that your customers are satisfied too. Whether it’s optical, pneumatic or electrical, we always choose the most appropriate measuring method for your complex task. Our measuring and testing systems record, visualize and statistically evaluate all measured values.

-

Optical/Tactile Measuring and Inspection System for Metal Parts

-

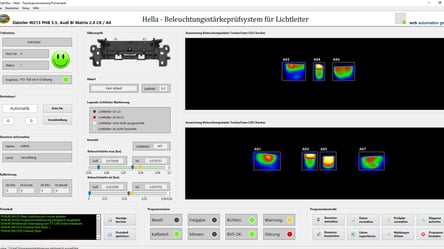

Light Guides Testing System

-

Testing System for Pump Housing

Reliable vane pumps are crucial for ensuring that vehicle power steering systems work safely. Our specially developed optical/tactile measuring and testing system measures precision metal parts for these vane pumps.

Measuring and Testing Tasks

- Measuring metal parts with the following test criteria

- Precise parts for

- Length tolerance ≤ 20 μm

- Squareness ≤ 10 μm

- Surface defects ≥ 35 μm

- Cycle time: 2 seconds

Technology

- Rotary indexing machine with 8 workstations

- Length measurement with touch probes

- Color-coded quick setup kits for different part sizes

- Surface control with 5 cameras

- Transmitting data to the MES in real time

- Visualizing extensive results

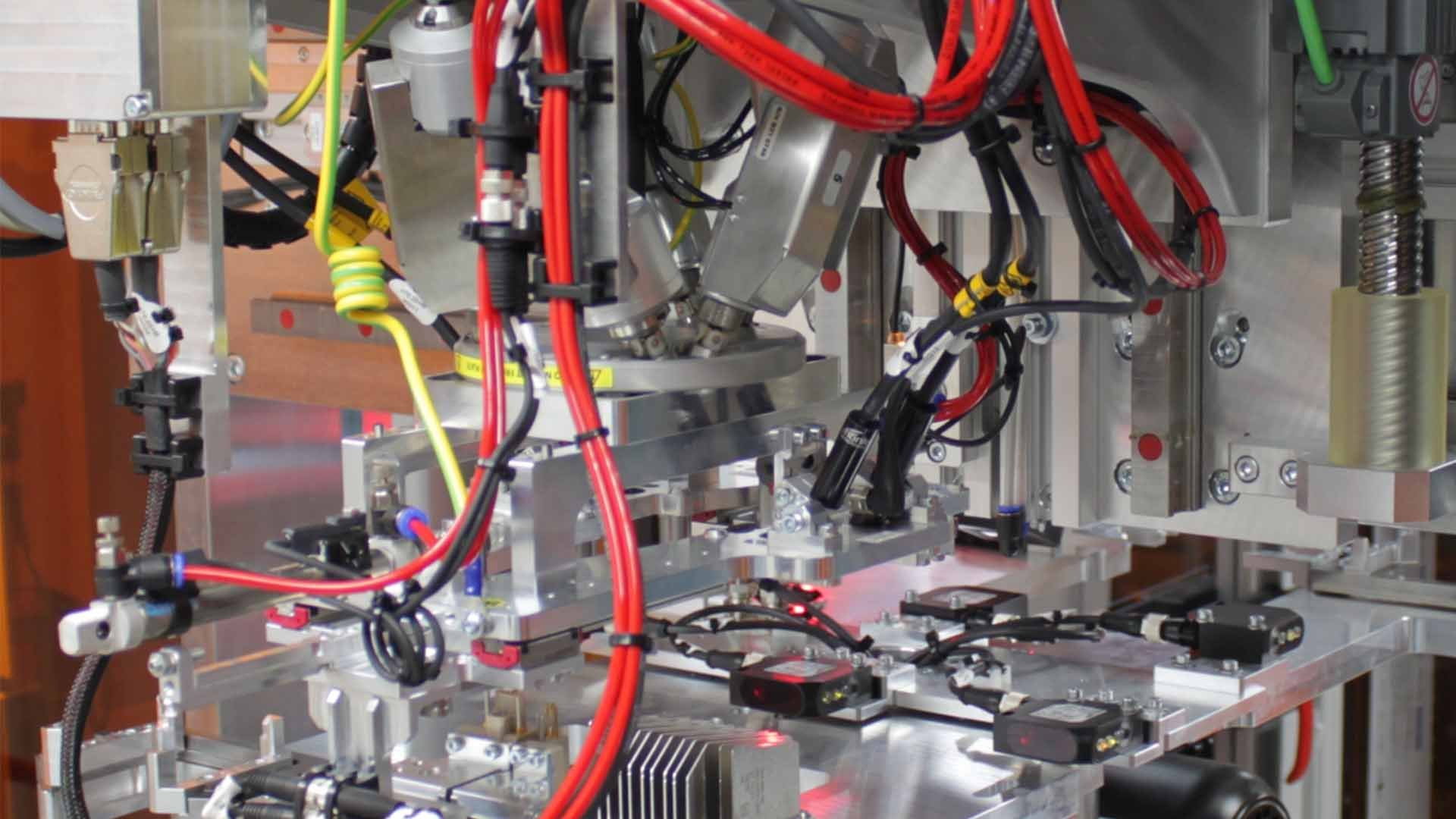

Our testing system guarantees fault-free light guides, resulting in outstanding LED headlight quality, so the road ahead of you always looks like it’s bathed in daylight, even at night.

Measurement Tasks

- Photometric and geometric testing for silicone optics and primary optic assemblies

- Measuring absolute or relative luminous flux, luminous intensity, illuminance

- Measuring the height profile and tilt of light entry surfaces

- System concepts in line with customer requirements (manual inserts, drawer concepts, tray stacking concepts, depositing on trays/blister packs, etc.)

Technology

- Fully automatic parts handling, automatic tray handling

- Automatic calibration with a golden sample

- Optimizing setups for supporting multiple models and variants

- Interchangeable setup parts monitoring based on RFID

- Automatic gripper change

- NC-controlled rotary indexing table

- Screwless setup

- Pre-centering stations

- Visualizing extensive results using LabVIEW

What’s required for ensuring that your pumps perform exceptionally well? Flawless parts. The MRB test system measures the pump housings, ensuring outstanding pump performance.

Measurement Tasks

- Outer and inner diameters

- Bore hole diameters

- Bore hole positions

- Concentricities of bore holes

- Clearance dimensions

- Leakage testing

- Chip/swarf monitoring

- Laser marking

Technology

- Rotary indexing machine with 12 workstations

- Parts feeding via a workpiece carrier system

- Tactile measurements

- Optical metrology

- Leakage testing

- Visualizing extensive results

- Statistical evaluations

- Connection to MES

-

Calibration System for Clinical Thermometers

-

Calibration System for High-Resolution Position Sensors

-

Angle Sensors

Regardless of the disease, fever is an indicator that must be taken seriously, as even the smallest change in temperature can influence the course of the disease and how medication is administered. Our specially developed calibration system for clinical thermometers guarantees the highest quality, and

exceptional safety.

Calibration Tasks

- Calibrating clinical thermometers in water baths with different temperatures

- Sorting raw thermometers for further processing

- Final thermometer testing

- Laser marking after OK test result

Technology

- Automatic thermometer feeding

- Water baths with temperature control accurate to one hundredth of a degree

- Measuring and testing thermometers with various camera systems

- Cycle belt with a 2.2-second cycle time

- Sorting the thermometers with high-speed delta robots

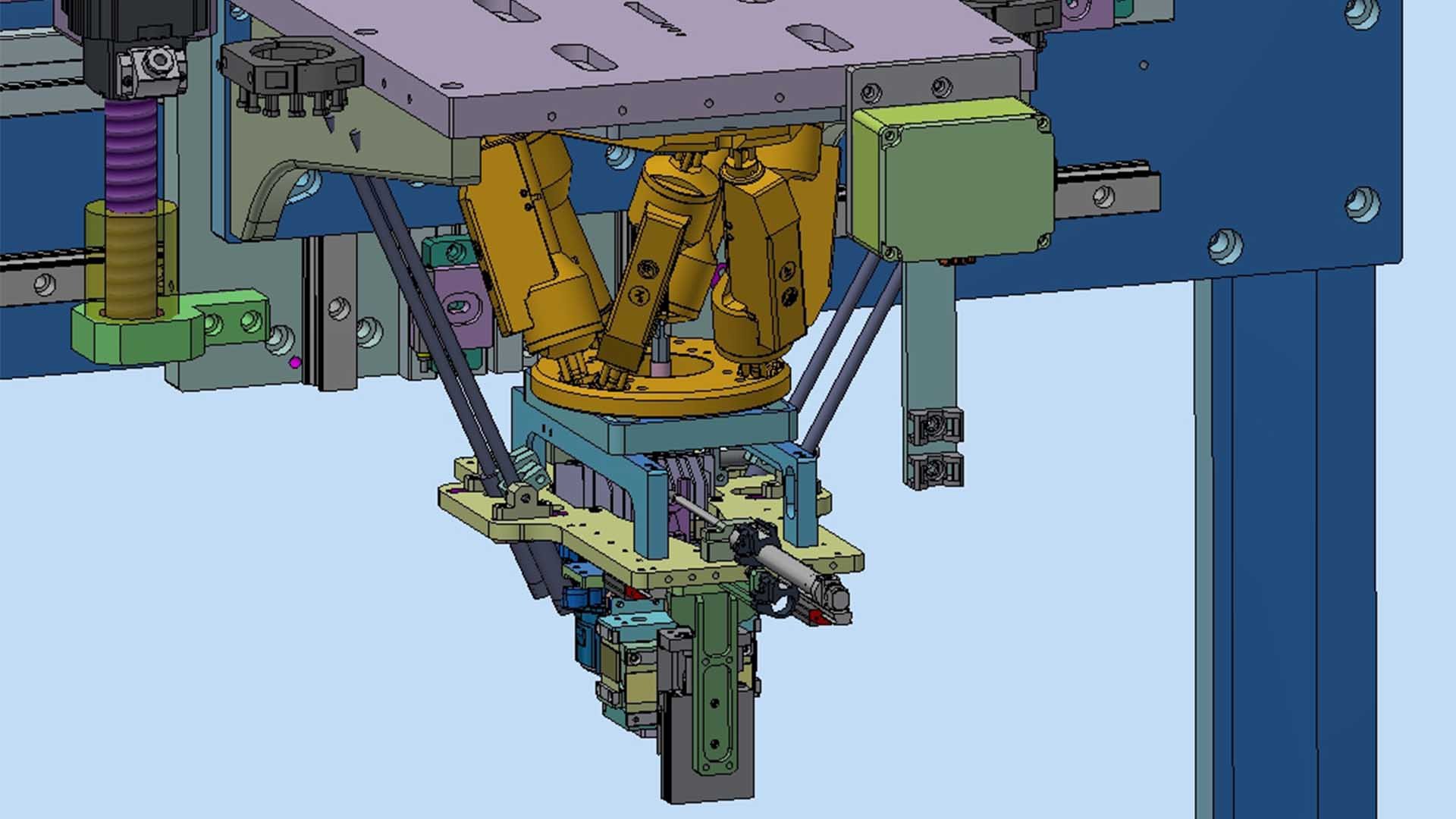

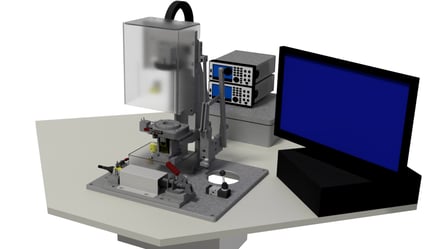

Position sensors measure how much milling machine spindles have been deflected during milling, ensuring high metal removal rates and reduced tool wear. The MRB calibration system calibrates these sensors with sub-micrometer accuracy to make sure everything works reliably and accurately.

Calibration Tasks

- Determining calibration curves for 3 axial and 3 radial sensors

- Verifying all parameters

- Updating firmware

- EEPROM programming

- Database storage

Technology

- Granite structure

- X/Y/Z piezo drives

- Position resolution 0.05 μm

- Measuring accuracy 0.05 μm

- Automatic centering functions

- Retrieving parameters from MES

- Parameterizing the firmware

- Programming the calibration curves on EEPROM

By developing a calibration system for hall sensors, MRB is able to ensure that trucks can safely negotiate bends.

Calibration Tasks

- Programming and calibrating Hall sensors for angle encoders

- Electrical tests

- Hysteresis tests

- Function tests

- Diagnostic functions

- EEPROM programming

Technology

- Type-dependent clamping elements and contacts

- Comprehensive LabVIEW program package

- Recipe management for different models

Unser Maschinenpark

Wir verfügen über modernste CNC-Maschinen mit integrierter CAD/CAM-Lösung. So können wir schnell und flexibel reagieren und Einzelteile sowie Kleinserien für Sie fertigen.

Unser Prozessmanagement

Höchste Qualität sowie die schnelle und einfache Abwicklung Ihres Auftrags stellen wir durch unser effizientes Prozessmanagement sicher. So wissen Sie immer, wo Sie dran sind – von der Anfragenbearbeitung bis zur Auftragsnachbearbeitung.

Wir setzen auf Qualität

Nicht nur bei der Entwicklung von Hochpräzisionsanlagen, sondern auch in der Fertigung steht Qualität bei uns an oberster Stelle. Ihr Auftrag liegt bei uns in exzellenten Händen.

Our Machinery

We have state-of-the-art CNC machines with a CAD/CAM solution built-in. This allows us to respondquickly and flexibly to produce custom parts, as well as in small series, whatever you need.

Our Process Management System

We always ensure the highest quality, and your order is processed quickly and efficiently via ourprocess management system. You always know where you stand – from having your inquiryprocessed, to following up your order.

We Focus on Quality

Quality is our top priority, not only when it comes to developing high precision systems, ourmanufacturing is top-of-the-line too. When you order from MRB, you’re in excellent hands.

Getting To Know MRB

How has MRB Automation managed to become an innovator for high precision systems? It's been acombination of strong expertise, many years of experience, and an amazing team. Find out more aboutMRB and what it's like to work in this team by clicking here.